Sunbright specializes in cnc processing, aluminum parts processing, CNC lathe processing, machining, precision parts processing, turning parts, turning parts processing, stainless steel parts processing, aluminum alloy processing, processing materials including but not limited to various types of stainless steel, aluminum alloy, yellow Copper, etc. The tolerance of CNC machinery precision shaft accessories we process can reach 0.005mm, and we can Suscipe customized processui de variis praecisione shaft accessiones secundum user necessitates.

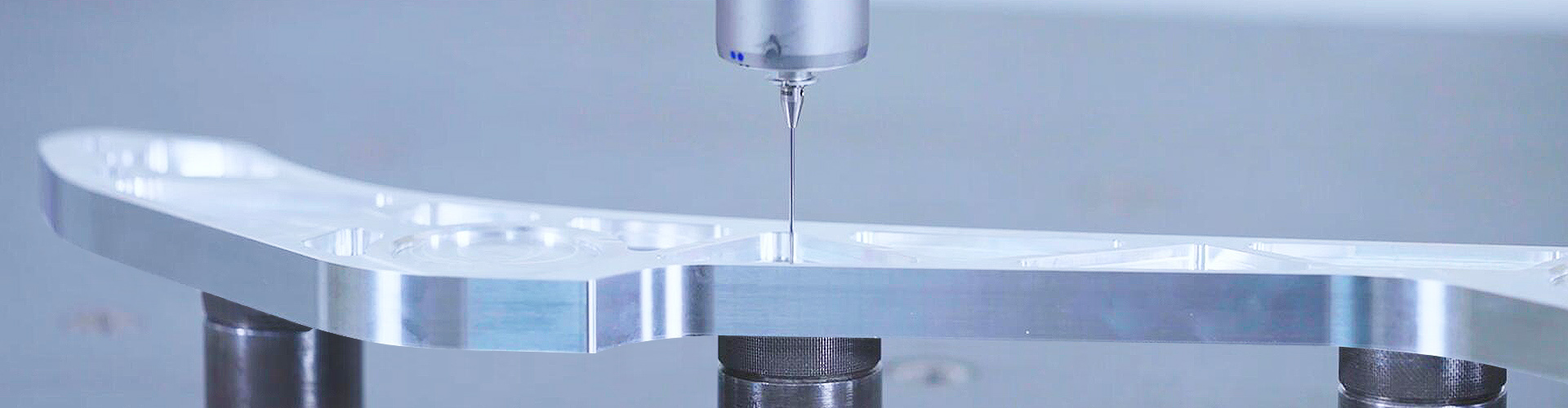

CNC Machinery Precision Shaft Accessories

Sunbright specializes in cnc processing, aluminum parts processing, CNC lathe processing, machining, precision parts processing, turning parts, turning parts processing, stainless steel parts processing, aluminum alloy processing, processing materials including but not limited to various types of stainless steel, aluminum alloy, yellow Copper, etc. The tolerance of CNC machinery precision shaft accessories we process can reach 0.005mm, and we can Suscipe customized processui de variis praecisione shaft accessiones secundum user necessitates.

Product Display

Product Introduction

1.Cnc Machinery Certamen Shaft Accessories sunt unus de typical partibus saepe congressi in machinis. Est maxime ad auxilium transmissionem partes, transmittendum torque et ursus onerat. CNC machinery precision shaft accessories are rotating body parts, whose length is greater than the diameter, generally composed of the outer cylindrical surface, conical surface, inner hole and thread and the corresponding end surface of the concentric shaft. Secundum diversas structuram et figura, cnc machinatione praecisione sutura accessiones dividitur in optical hastile, egressus hastile, cavae hastile et crankshaft.

2.cnc machinatione praecisione hastile accusies debet eligere diversas materiae et capere diversis calor curatio specifications (ut extinguantur et temperatio, normalizing, extinguendas, etc.) secundum diversas operantes conditionibus et usum resistentia. XLV Steel est commune materia ad CNC machinery praecisione sutura accessiones. Post extinguere et temperatio (vel normalizing), potest consequi melius cutting perficientur, et potest obtinere comprehensive mechanica proprietatibus ut altus vires et lenta. Post extinguere, superficiem duritiam usque ad XLV ~ 52hrc. Mixy structural ferro ut 40cr apta cnc machina praecisione sutura accessories cum medium praecisione et celeritate. Post extinguendas, temperatio et extinguendo, hoc genus ferro habet melius comprehensive mechanica proprietatibus. Bearing steel GCr15 and spring 65Mn, after quenching and tempering and surface high-frequency quenching, the surface hardness can reach 50~58HRC, and it has high fatigue resistance and good wear resistance, and can manufacture high-precision shafts. 38cmoaia nitrided ferro potest electus ad fusum ex praecisione machine instrumenta (ut molere rotam rotam et molere machina et fusum coordinare odiosis machina). Post extinguere et temperatio et superficies nitriding, quod ferro non solum obtinere excelsum superficiem duritiam, sed etiam ponere mollis core, ita habet bonum impulsum lenta. Comparari cum carburized et extinguatur ferro, habet characteres de parva calor curatio deformatio et superior duritia.

Product tolerantia:+/- 0.005mm

Faq

Quis sumus?

Shenzhen Sunbright Technology Co., Ltd. est a metallum partes manufacturer integrating progressionem, consilio, productio et venditionesque. In comitatu est provectus FORMULTOR vestibulum et mittentem mori-casting, cudent, stridet, extrusionem, conversus et milling compositum cnc machining, etc. productum coetu vestibulum elit. Products late in communications, instrumenta, medicinae apparatu, summus celeritate blasphemiæ, impedimenta, automobiles, aviation, automation apparatu et alia industries. Secundum necessitates customers, ut providere unum-subsisto officia ut productionem, dispensando, politicitatem, oleum iniectio, corrosio, electroplating et cœnaculo et hardware metallum partes.

Quid servicia possumus providere?

We can provide CNC turning, milling, turning and milling composite services, our metal mold processing services include stamping, die casting, forging, casting, powder metallurgy, and we also provide injection molding services, etc. We can provide you with more than 50 kinds of metals and plastics Materials, our more than two dozen surface treatments including electroplating, anodizing, painting, etc., can tailor a part solution for you according to your needs.

Quid enim praestare qualis?

Sunbright has successively passed ISO9001 certification, passed AS9100 aerospace quality management system standard certification, NDT-MT passed NADCAP certification, introduced ERP system in 2018, and implemented lean production in 2020. The company has a professional management team, strong technical force, advanced Production equipment, high-precision monitoring and measuring equipment, and perfect management system provide customers with high-quality products and Services.

Quod apparatu non habemus?

Sunbright has more than 1,000 sets of CNC machining, EDM, punch, die-casting machines, forging equipment, casting equipment, and injection molding equipment, which can manufacture high-precision parts for you.Our testing equipment includes German ZEISS CMM three-coordinate instrument, German SPECTRO MAXx06 Spectrometer direct reading spectrometer, American Micro-Vu CMM optical three-coordinate instrument; American AD-MMXLV Horizontal Magnetic Detector, American Projector, Japan Mitutoyo Profilometer, American Pneumatic mensuræ instrumentum, Italica ratio affirmat duritiam, Germanica Gardner et alia praecisione testis apparatu.